Maximator Test offers a full range of high pressure testing services, including Leak Testing, Burst Testing, and Pressure Pulse Testing. Our mission is to provide unrivaled service to our customers in achieving their testing needs. Our maxim is “under promise, over deliver.” We will go above and beyond to help you meet your deadlines.

High Pressure Testing Services

Pressure Fatigue Testing | Impulse Pressure Testing

One of the prime benefits of pressure fatigue testing is determining the “weak link” in a product’s design. In some cases, it may come as a surprise as to the actual location of the weakest part of a component.

Characteristics such as surface finish may have a much more profound impact on fatigue life than most designers suspect. High surface loading near gaskets and seals can hold significant mean stress levels, adversely effecting fatigue life.

Burst Testing

A destructive test, burst testing establishes the pressure at which the component or system sustains permanent deformation, and finally the pressure at which it fails. It also establishes how it fails – by leaking, catastrophic failure etc. Burst testing is the ultimate design check. (You make it, we break it!)

Proof Testing

A non-destructive test, proof-testing verifies that a component or system is capable of withstanding a pressure slightly above the design or operating pressure without permanent damage or leaking.

Proof Testing is like a “Stamp of Approval”.

Leak Testing

Really a form of proof testing, leak testing requires that the part be pressurized and checked for leaks. Often this is done by immersing the part in a clear liquid (usually water), pressurizing with air, nitrogen or helium, and watching for leaks. This is a simple and versatile test. A stage further is to use helium and a mass spectrometer device to check for leaks. This is very sensitive, and provides a quantitative assessment of any leak, but it requires extensive fixturing.

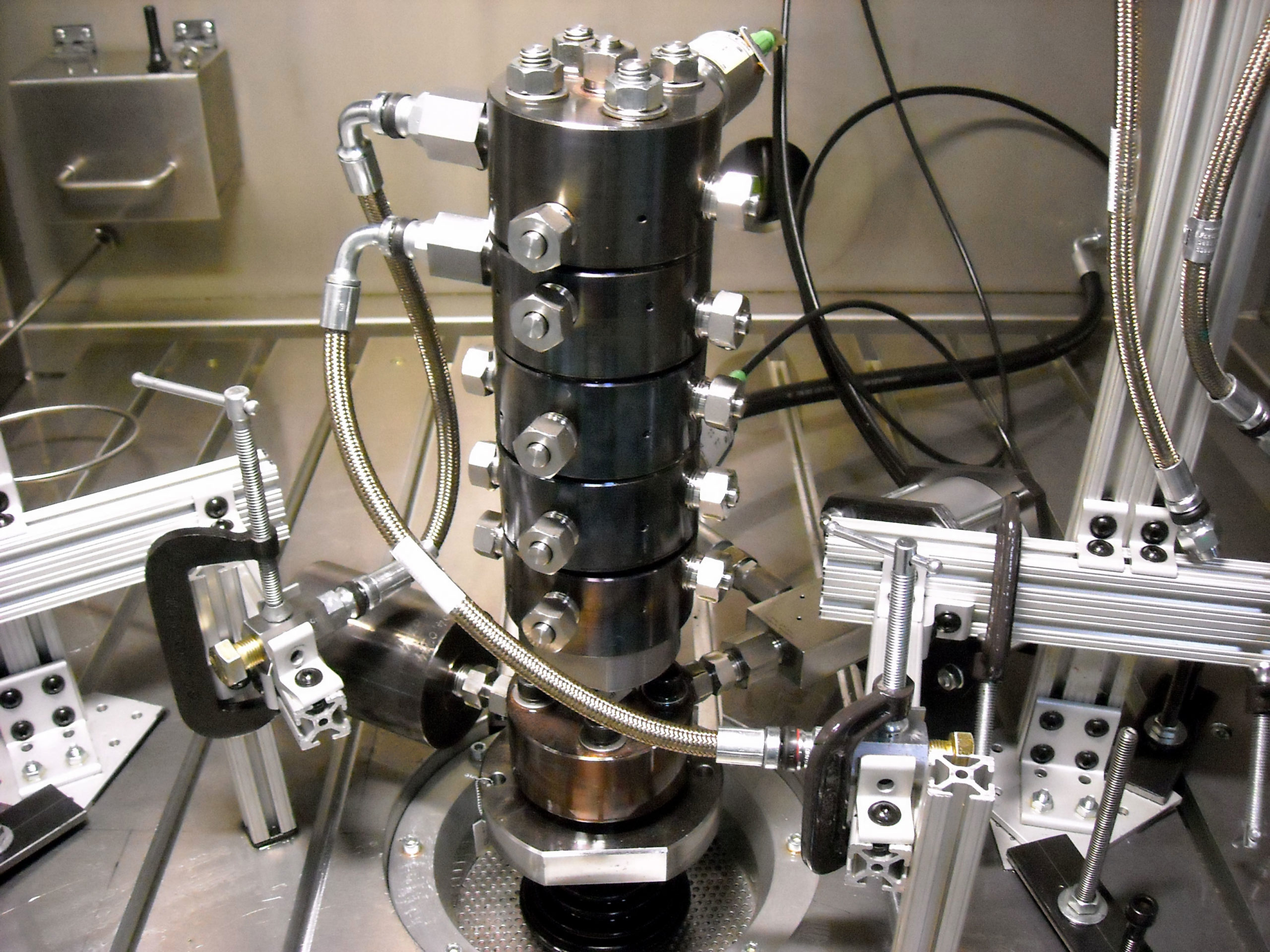

Fixture Adapter Assistance

Maximator Test can provide design support for many sealing fixture applications. If your company has fabrication abilities, we can work with you on a fixture design that you can build in-house. We can also fabricate the fixture for you through our trusted local ISO9001:2015 machine shop.

Autofrettage

The fatigue life of thick-walled, high strength, high pressure components can often be substantially improved by an initial pressurization high enough to yield the bore area. This process takes advantage of the stress variation across the wall of a thick-walled cylinder: the stresses are much higher at the bore than at the outside. As the pressure in increased, there comes a point where the material near the bore yields, but the rest of the wall is still elastic. When the pressure is released, the material at the bore winds up with residual compressive stresses.

Dye Penetrant Testing

Dye penetrant testing, also known as DP testing, DPI (Dye-Penetrant Inspection) can be a valuable tool to help determine the exact failure location of a test sample.

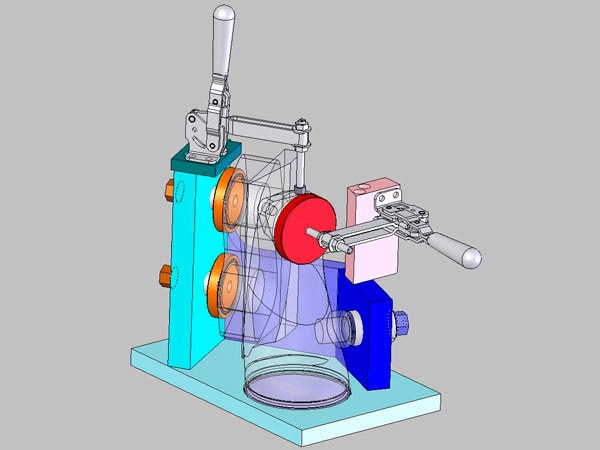

Plastic Part Testing

MAXIMATOR TEST along with our partners at TiK Germany can work with you to develop a pressure testing procedure for your components. Our long term experience in plastics technology and mold manufacturing can help you reduce your time-to-market, saving you time and money.