Fixture Design & Fabrication

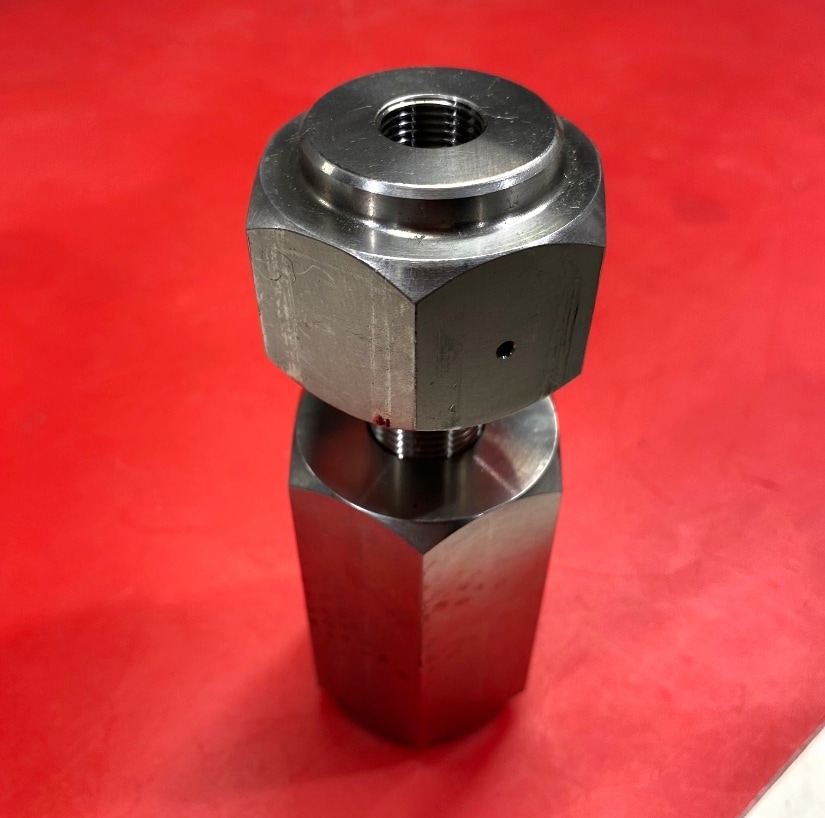

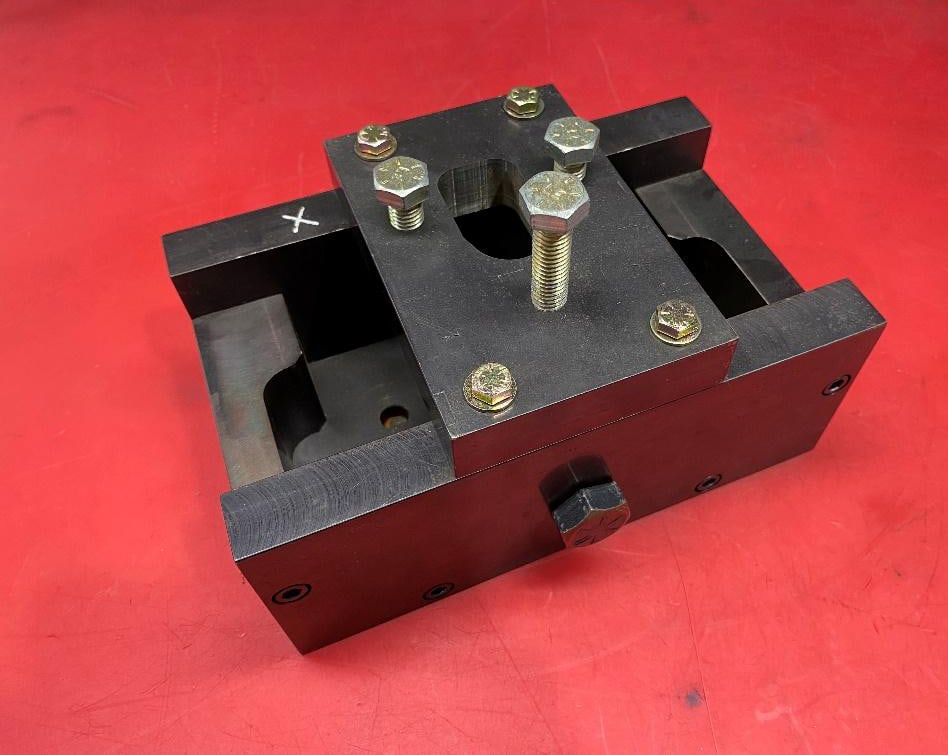

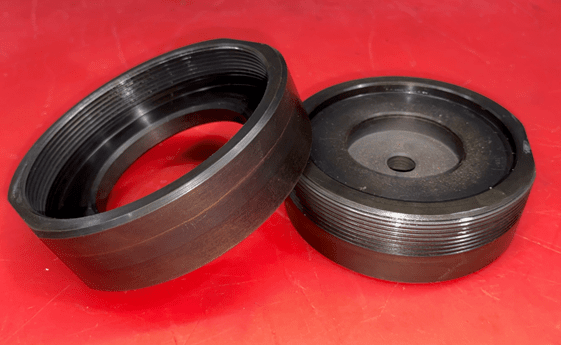

Are you a design or quality engineer who needs to have a component Burst, Leak, Proof or Pressure Fatigue tested? We work with customers across many industries including Aerospace, Automotive, Chemical, Defense, Medical and Oil & Gas, that require us to design sealing technologies. These sealing designs could be for a specific application like Autofrettage of fluid ends for hydraulic fracturing, adapters that will connect your samples to our high-pressure testing equipment, holding fixtures to constrain the endpoints of a part for pressure testing, or a complete sealing fixture to burst test a component.

If your company has fabrication capabilities, we can develop the design of a sealing fixture that you build in-house, or we can have the fabrication completed by our trusted local ISO 9001:2015 registered machine shop. Please see below for some of the fixtures designed and fabricated by Maximator Test.